- Quenching and Tempering

- Normalizing

- ISO thermal Treatment

- Stress-Relieving Annealing(SRA)

- Spheroidizing

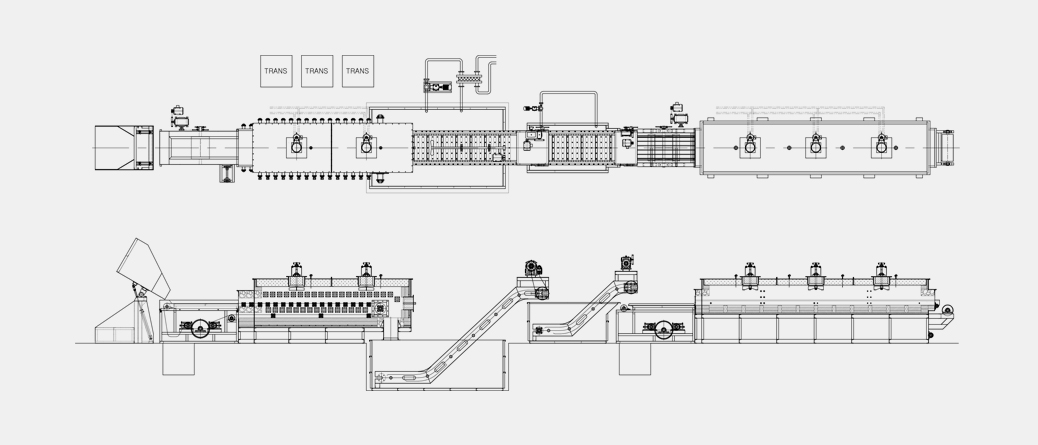

Quenching and Tempering

Definition

Quenching refers to the process of heating metal parts at a high temperature, maintaining their temperature, and letting them cool down immediately in a cooling medium (oil or water). Metal parts are reheated after quenching; toughness is improved during this process, which is called tempering. The strength obtained through quench hardening is not high, and metal parts are reheated to improve the toughness of the internal microstructure. Quenching and tempering are paired up and performed, and is called quenching and tempering (QT).

1) Quenching

It is a heat treatment process in which the entire austenite or some of it are transformed to martensite

and hardened through immediate cooling after austenitizing steel. The austenitizing temperature for hypoeutectoid

steel should be Ac₃ hypoeutectoid steel, and the quenching temperature for it should be set between Ac₁ and

Acm. There are water quenching, oil quenching, martempering, and austempering as quenching methods. Select a

quenching medium and a method, and perform it depending on the materials and product properties.

2) Tempering

It is a heat treatment process of reheating a quench-hardened steel below the eutectic temperature,

keeping it at that temperature for an appropriate period, and air cooling immediately to improve ductility

and toughness, remove residual stress, and stabilize a structure.

Feature

It is commonly used in the mass-production of small products of 5 kg unit weight or less. It requires fewer personnel due to easy operation through automation. Non-oxidizing is available by using CH3OH, RX-GAS, and DX-GAS for ambient gas.

Business

Business