Laser heat treatment

- Introduction to Laser Heat

Treatment Technology - Comparison of laser heat treatment

and induction heat treatment - Laser heat treatment equipment

and technical manpower - Laser Heat

Treatment Features - Process reduction

and cost reduction

SANGDO TDS Co., Ltd.’s Laser Heat Treatment

Establishment of laser heat treatment system with Korea Institute of Machinery and Materials

In 2018, we participated in a future machine technology planning project of the Korea Institute of Machinery and Materials (KIMM) to build a laser heat treatment system and to carry out R&D under the condition of purchasing a national project, and are focusing on laser heat treatment production and technology development for various products such as molds and industrial machinery parts.

Signed overseas technology partnership signed and selected as KIMM family company

In order to exchange global market trends and technologies, we have signed a technical partnership with Fuji Koushuha Industry Co., Ltd. a leading Japanese company in laser heat treatment.

In addition, by being selected as a family company by the KIMM in 2021, we are doing our best to provide the value demanded by demand industries faster through industry-academia-research collaboration at home and abroad.

In addition, by being selected as a family company by the KIMM in 2021, we are doing our best to provide the value demanded by demand industries faster through industry-academia-research collaboration at home and abroad.

Filed patent applications and received “New Technology-Excellent Secondary Contractor Prize” from Hyundai-Kia Motors

We have completed patent applications for ‘Method for Surface Hardening of Metal Base Material’ and ‘Laser Hardening System for Metal Base Material,’ and are accumulating records of delivery for laser heat treatment to extend the lifespan of press molds and various industrial machinery products and reduce costs. In 2021, we were recognized for our technological prowess to the extent that SANDO TDS was selected as a secondary contractor or supplier for excellent new technology by Hyundai and Kia Motors for the development of laser heat treatment technology for cast iron molds.

Laser Heat Treatment Equipment and Technology Personnel

Laser heat treatment equipment and working range

Let us introduce our laser heat treatment equipment.

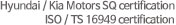

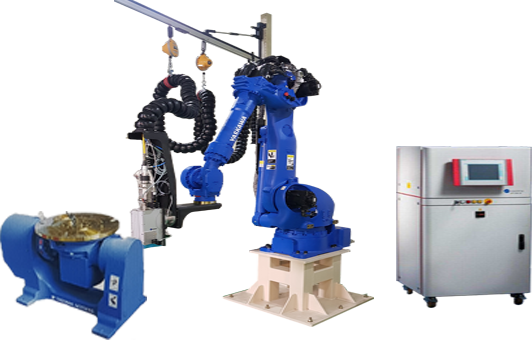

We have established a 6Kw diode laser from Laserline GmbH in Germany, which is the most efficient for heat treatment, for laser sources; variable types of 8 to 42mm and 16 combinations of 3x3 to 8x22mm for beam size; and Yaskawa’s 6-axis robot and 2-axis positioner and carriage, and such equipment can work up to 7m in width and 2m in length.

We have established a 6Kw diode laser from Laserline GmbH in Germany, which is the most efficient for heat treatment, for laser sources; variable types of 8 to 42mm and 16 combinations of 3x3 to 8x22mm for beam size; and Yaskawa’s 6-axis robot and 2-axis positioner and carriage, and such equipment can work up to 7m in width and 2m in length.

| Classification | Item | Details |

|---|---|---|

| Laser | Manufacturer | Laserline GmbH |

| Output | 6Kw | |

| Transmission mode | Diode Laser | |

| Heat treatment rate | 4 to 8mm/sec (depending on materials and requirements) | |

| Beam size (mm) | 8 to 42mm variable, 3x3 to 8x28mm (16 combinations) | |

| Adjustment distance | 250 ± 1mm | |

| Robot | Manufacturer | YASKAWA(6-axis) MOTOMAN - MH180 |

| Working range | 3,000 × 2,000mm | |

| Precision | No robot tolerance Tolerance due to tools or vibrations |

|

| Temperature control | Measurement method | Pyromer (infrared thermometer) |

| Control method | Temperature control | |

| Working range | Horizontal | Utilization of robot carriages 7,000mm |

| Vertical | 400 ~ 2,000mm |

Top-notch heat treatment technicians

Given the uniform quality, treatment time, and treatment requirements before and after heat treatment, laser heat treatment is a cost-effective heat treatment technology. A combination of the heat treatment technology to improve product quality and prolong the life of the product and the engineering process of skilled technicians is an important part of manufacturing processes in various industries. We are focusing on laser heat treatment with industry-leading technical personnel with extensive field experience and understanding of the characteristics of metal materials and various heat treatment processes.

|

|

Business

Business