Laser heat treatment

- Introduction to Laser Heat

Treatment Technology - Comparison of laser heat treatment

and induction heat treatment - Laser heat treatment equipment

and technical manpower - Laser Heat

Treatment Features - Process reduction

and cost reduction

Laser Heat Treatment Features

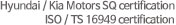

Laser heat treatment is possible for only parts that need hardening

A relevant product needed the hardening of the surface between the holes.

In the case of high-frequency heat treatment, there is a risk of size change due to heat effect on the central hole. In addition, it entails a risk of welding due to cracks in small holes in the corners of the heat-treated area. Therefore, as the risk of defects is increased with the existing partial heat treatment methods such as high-frequency heat treatment, SKD11 is used to heat-treat a part that needs hardening with a vacuum to perform full-hardening heat treatment.

Because laser heat treatment treats only the part that needs hardening, heat treatment shown in the picture is possible. Therefore, the material can be changed from SKD11 to S45C, reducing the cost of materials.

In the case of high-frequency heat treatment, there is a risk of size change due to heat effect on the central hole. In addition, it entails a risk of welding due to cracks in small holes in the corners of the heat-treated area. Therefore, as the risk of defects is increased with the existing partial heat treatment methods such as high-frequency heat treatment, SKD11 is used to heat-treat a part that needs hardening with a vacuum to perform full-hardening heat treatment.

Because laser heat treatment treats only the part that needs hardening, heat treatment shown in the picture is possible. Therefore, the material can be changed from SKD11 to S45C, reducing the cost of materials.

Material: S45C

Material: S45CHardness: HRC60

Case depth: 0.5mm

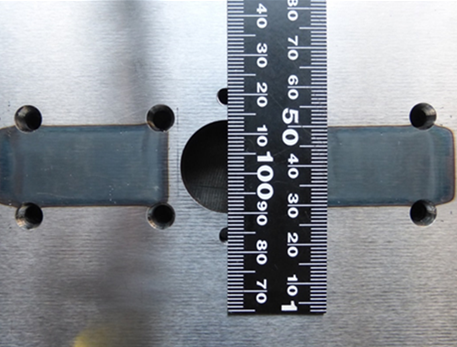

Less deformation after Heat Treatment

Small deformation after the heat treatment is performed is a characteristic of laser heat treatment.

This is an example of extending the life of products by applying laser heat treatment that causes little deformation to the part that is problematic due to warping or distortion when the high-frequency heat treatment method is used for the interlocking surface.

This is an example of extending the life of products by applying laser heat treatment that causes little deformation to the part that is problematic due to warping or distortion when the high-frequency heat treatment method is used for the interlocking surface.

Material: S45C

Material: S45CHardness: HRC60

Case depth: 0.5mm

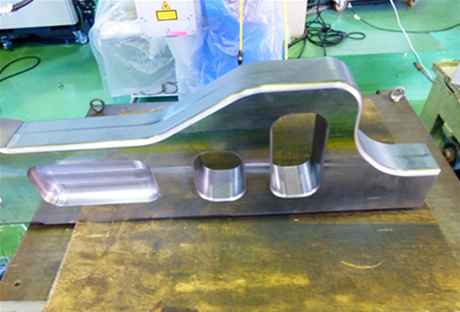

Laser Heat Treatment Possible for Complex Shapes

Laser heat treatment is capable of heat-treating complex shapes.

The product in the photo on the right requires hardening of the curved upper surface.

In high-frequency heat treatment, it is exceedingly difficult to move the heat treatment coil according to this complex shape. In addition, a cost of millions of won is required in high-frequency heat treatment to manufacture a dedicated coil, which increases the cost of heat treatment for a single unit.

If the laser heat treatment method is used, the robot can teach, so even these complex types of work can be heat-treated more stably.

The product in the photo on the right requires hardening of the curved upper surface.

In high-frequency heat treatment, it is exceedingly difficult to move the heat treatment coil according to this complex shape. In addition, a cost of millions of won is required in high-frequency heat treatment to manufacture a dedicated coil, which increases the cost of heat treatment for a single unit.

If the laser heat treatment method is used, the robot can teach, so even these complex types of work can be heat-treated more stably.

Material: S45C

Material: S45CHardness: HRC60

Case depth: 0.5mm

Business

Business