Laser heat treatment

- Introduction to Laser Heat

Treatment Technology - Comparison of laser heat treatment

and induction heat treatment - Laser heat treatment equipment

and technical manpower - Laser Heat

Treatment Features - Process reduction

and cost reduction

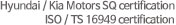

Process reduction and cost reduction

Cost Reduction and Lead Time Shortening by Curtailment of Laser Heat Treatment Process

A typical process for metal parts to be completed is shown in the figure below.

Products that do not have problems with laser heat treatment can reduce costs and lead time by shortening processes after the finishing machining due to minimal deformation and distortion reduction.

Products that do not have problems with laser heat treatment can reduce costs and lead time by shortening processes after the finishing machining due to minimal deformation and distortion reduction.

Example of Process Shortening with Laser Heat Treatment of Carriage Plate

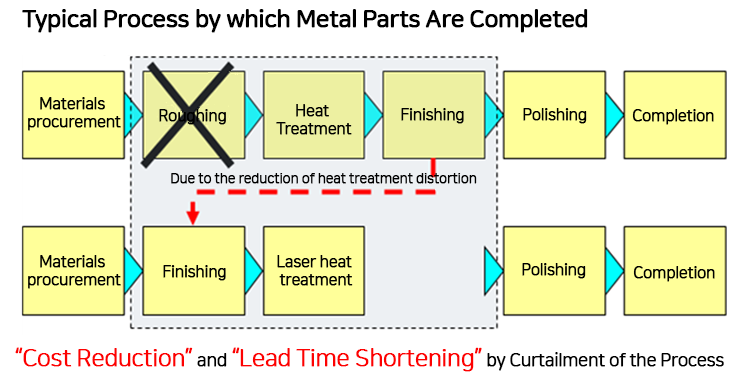

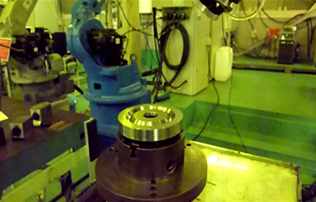

The deformation of the product after laser heat treatment of the V-groove part of the carriage plate below is 0.1mm or blow, and this case shows that the roughing machining can be omitted through laser heat treatment after the finishing machining.

Laser heat treatment can curtail the process due to deformation decrease which is a characteristic of laser heat treatment, thereby reducing cost and lead time. A number of advantages can be gained only by the reduction of heat treatment deformation.

Laser heat treatment can curtail the process due to deformation decrease which is a characteristic of laser heat treatment, thereby reducing cost and lead time. A number of advantages can be gained only by the reduction of heat treatment deformation.

Laser heat treatment of the carriage plate V-groove

Laser heat treatment of the carriage plate V-grooveMaterial : S45C

Hardness : HRC60

Case depth : 0.3~0.8㎜

Deformation after laser heat treatment: 0.1 mm or less

Process Shortening and Cost Reduction by Laser Heat Treatment(Japanese case)

The chart below is a Japanese case comparing high-frequency heat treatment and laser heat treatment processes.

Laser heat treatment makes it possible to complete the process up to the finishing machining at one time before heat treatment, shortening the total process period by 2 days from 10 days to 8 days, and reducing the total cost by more than 20% from 14,000 yen to 11,000 yen.

A number of advantages can be gained only by the reduction of heat treatment deformation.

Laser heat treatment makes it possible to complete the process up to the finishing machining at one time before heat treatment, shortening the total process period by 2 days from 10 days to 8 days, and reducing the total cost by more than 20% from 14,000 yen to 11,000 yen.

A number of advantages can be gained only by the reduction of heat treatment deformation.

Unit: yen (¥)

| Process | High-frequency heat treatment | Laser heat treatment | Laser Heat Treatment Features and Benefits |

|---|---|---|---|

| ① Procurement of materials | 1,500 | 1,500 | |

| ② Roughing (machining) | 6,000 | 7,500 Up to the finishing (machining) |

Making it possible to complete the process up to the finishing at one time; However, the machining cost rises. |

| ③ Heat treatment | 1,500 In some cases, 30,000 yen is added for coil cost. |

2,000 | |

| ④ Finishing (machining) | 5,000 | 0 No machining after heat treatment |

No post-machining is required, so it is possible to shorten the construction period by 2 to 3 days and reduce transportation costs |

| Total cost | @14,000 Construction period about 10 days in total |

@11,000 Construction period about 8 days in total |

About 20% cost reduced from total cost Construction period reduced by 2 days |

A number of advantages can be gained only by the reduction of heat treatment deformation.

Material provided by: Fuji Koushuha Industry Co., Ltd.

Business

Business